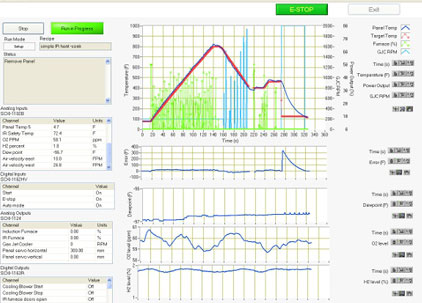

Controls motion, heating, cooling and logs data from a 1/10th scale simulator of steel manufacturing facility. Steel panels move between various heating and coating stations inside of a sealed atmospheric chamber.

Features

- Controls 2 axis motion, IR and Induction furnaces, and gas jet cooler

- Uses PID control to optimize heating and cooling of steel panels

- Utilizes user defined Recipes which allow complete control of the steel panel temperature profile over time, along with control of panel coating & heating sequences

Contact us today to discuss your unique situation.